- Products Details

Quick Details

-

Brand Name: BEDEL

Model Number: 001

Place of Origin: Jiangsu, China (Mainland)

Packaging & Delivery

- Packaging Details: Strong Plywood Case With Steel Frame

- Delivery Detail: shipped in 30 days after payment

Specifications

Production Description

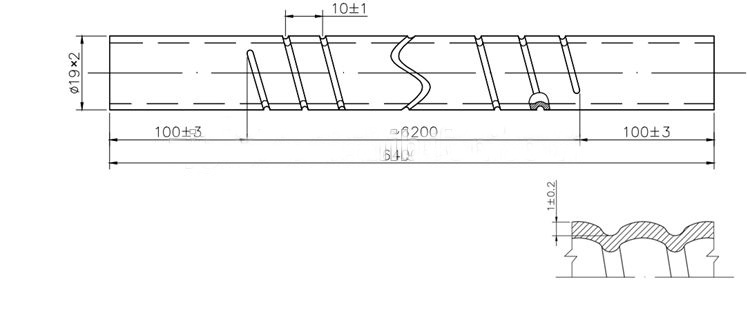

| Product Name | Spiral Fin Tube |

| Material | Copper, Aluminum, e.tc |

| Type | Extruded |

| Packing | Strong Plywood Case With Steel Frame |

| MOQ | 100 Meter |

| Warranty | 1 Year |

| Payment | T/T,L/C |

| Application | Heater,Heat Exchanger Parts etc |

| One Of Reference Drawing |  |

|

Extruded Copper or Aluminium Sprial Fin Tube In Heat Exchanger Parts Spiral Fin Tube Due to the features that higher heat transfer coefficient, larger heat transfer area and less consumption of steel etc, Threaded pipe has been recognized as a kind of strengthening heat transfer element. The research report pointed out that the design of is reasonable. So the flue gas heat transfer efficiency of threaded pipe is 1. 6 times of light tube. Because the threaded pipe has the remarkable characteristics, it has been more and more widely used in boiler manufacture. Features: (1) The heat transfer of a thread smoke tube is as the same as that of 1.7 to 1.8 root ordinary pipes after application of the optimization of heat transfer and flow resistance when it is used on the boiler. This not only can reduce the pipe numbers, but also can lessen the diameter of the pot shell, thus, to save the steel and to cut down capital. (2) The heat transfer surface area is 1.5 to 2.0 times of the light pipe, this greatly improves the activity of the cooling methods and strengthen the tube inside boiling and condensation transfer effects in the application of air conditioning refrigeration industry. (3)Setting up in heat exchange equipment application on decoration, steel or stainless steel tube through a molding machine rolling, spiral tube fouling are spiraling in appearance, set decoration equipment running line temperature changes make the pipe produces expansion and contraction, thus can make the dirt to fall off; For the cylinder and the light pipe scale layer, without the power off. |

Workshop

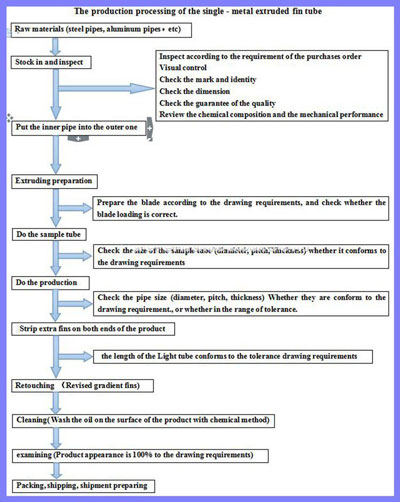

Production Flow Chart

Product

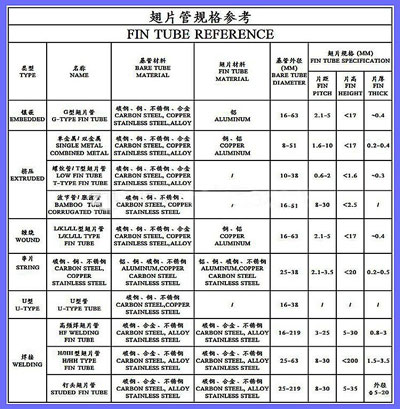

| FIN TUBE REFERENCE | |||||||

| TYPE | NAME |

BARE TUBE MATERIAL |

FIN TUBE MATERIAL |

BARE TUBE DIAMETER (MM) |

FIN SPECIFICATION (MM) | ||

| FIN PITCH | FIN HEIGHT | FIN THICK | |||||

| EMBEDDED | G-TYPE FIN TUEB |

CARBON STEEL COPPER,STAINLESS STEEL,ALLOY |

ALUMINUM | 16-63 | 2.1-5 | <17 | ~0.4 |

| EXTRUDED | SINGLE METAL COMBINED METAL |

CARBON STEEL, COPPER STAINLESS STEEL,ALLOY |

COPPER ALUMINUM |

8-51 | 1.6-10 | <17 | 0.2-0.4 |

| LOW FIN TUBE T-TYPE FIN TUBE |

CARBON STEEL, COPPER STAINLESS STEEL,ALLOY |

/ | 10-38 | 0.6-2 | <1.6 | ~0.3 | |

| BAMBOO TUBE CORRUGATED TUBE |

CARBON STEEL,COPPER STAINLESS STEEL |

/ | 16-51 | 8-30 | <2.5 | / | |

| WOUND | L/KL/LL TYPE FIN TUBE |

CARBON STEEL, COPPER STAINLESS STEEL,ALLOY |

COPPER ALUMINUM |

16-63 | 2.1-5 | <17 | ~0.4 |

| STRING | STRING FIN TUBE | ALUMINUM,COPPER CARBON STEEL STAINLESS STEEL |

ALUMINUM,COPPER CARBON STEEL STAINLESS STEEL |

25-38 | 2.1-3.5 | <20 | 0.2-0.5 |

| U-TYPE | U-TYPE TUBE | CARBON STEEL,COPPER STAINLESS STEEL |

/ | 16-38 | / | / | / |

| WELDING | HF-WELDING FIN TUBE |

CARBON STEEL, ALLOY STAINLESS STEEL |

CARBON STEEL, ALLOY STAINLESS STEEL |

16-219 | 3-25 | 5-30 | 0.8-3 |

| H/HH TYPE FIN TUBE |

CARBON STEEL, ALLOY STAINLESS STEEL |

CARBON STEEL, ALLOY STAINLESS STEEL |

25-63 | 8-30 | <200 | 1.5-3.5 | |

| STUDED FIN TUBE | CARBON STEEL, ALLOY STAINLESS STEEL |

CARBON STEEL, ALLOY STAINLESS STEEL |

25-219 | 8-30 | 5-35 | Φ5-20 | |

Packing

Packing Material (General)

| Name | Effect |

| Plastic Mat | Protection from compressional deformation for Fin Tube itself Dimension:5mm(Thick)*100mm(Width) |

| Waterproof Paper | Protection from water in shipping |

| Plywood | For packing wall 8mm(Thick) |

| Square Steel | For packing frame 2.7mm(Thick)*80mm(Width)*40mm(Height) 2.7mm(Thick)*30mm(Width)*60mm(Height) |

Shipping

Shipped By Container

Shipped By Bulk Vessel

Company Introduction

|

Zhangjiagang Bedel Heat Exchanger Equipment Technology Co., Ltd. is located in Yangtze River Delta, bordering the international metropolis Shanghai in the east, Our company is a professional manufacturer of various fin tubes for air cooler and heat exchanger and also provides heat exchanger equipments & parts and technical solutions.We have established long-term cooperation with the Taiwan Fengding industrial Co., Ltd.,and Hangzhou Boiler Group Co., Ltd. and we have maintained a stable and cooperative relations with many companies. Some products export Southeast Asia, Middle East, South America and North America etc. Our products are widely used in Sinopec, Petrochina, CNOOC, electric power, metallurgy and other industries. Due to the high quality of our products, fast and punctual delivery, reasonable price and good after-sales service, our company has acquired the recognition of the industry and the trust of our clients. Our company has passed the ISO9001:2008 Quality System Certification with advanced equipments, strong R&D strength, professional skill, perfect quality guarantee system and strict test. |

Certification

FAQ

|

Q1:Are you a factory or trade company?

Q2: What can you provide?

Q3:Where is your factory?

Q4: How do you control quality?

Q5: What are the advantages of your company?

Q6: Can you arrange the shipment?

Q7: How about the delivery time?

Q8: Can you provide sample? |

Scale: 11 - 50 People

Country/Region: China (Mainland)/Asia

Established:

US 500-5000 / Set 1 Set/Sets (Min.Order)

US 500-5000 / Set 1 Set/Sets (Min.Order)

US 500-5000 / Set 1 Set/Sets (Min.Order)

US 500-5000 / Set 1 Set/Sets (Min.Order)

US 500-5000 / Set 1 Set/Sets (Min.Order)

US 500-5000 / Set 1 Set/Sets (Min.Order)

US 500-5000 / Set 1 Set/Sets (Min.Order)